Hot Stamping Labels: The Best Way To Elevating Brand Presence with Metallic Sheen

Various decoration methods can improve quality perception and increase a brand’s shelf appeal.

In the highly competitive world of consumer products, the appeal of a brand’s label can make a lasting impression. Hot stamping effects labels are one of the most sought-after techniques to achieve an eye-catching design that attracts customers. Utilizing a process that involves heat and metallic foils, hot stamping creates labels that not only look luxurious but also enhance a product’s perceived value. This method has become increasingly popular across various industries, including cosmetics, food and beverage, and luxury goods. Let’s dive into the world of hot stamping effects labels and explore how they work, their benefits, and the latest trends shaping the industry.

There is a science behind applying metallic effects, too. There have been many studies conducted that show foil decoration increases purchases versus traditional print by 40%, and the likelihood of positive eye tracking results by up to 80%. For example : Wine and spirits have already exhibited how transforming the perceived value of the product is achievable through foil decoration. Including foil and embossing effects into the design gives a unique and premium look with visibly tactile brilliance and texture.

Understanding the Hot Stamping Process

Hot stamping, also known as foil stamping, is a technique where heat, pressure, and metallic foils combine to transfer a design onto a surface, creating a shiny, reflective finish. This technique can be applied to paper, plastic, and other materials, making it versatile for different types of product labels.

The process involves placing a metallic or pigmented foil between a heated die and the label material. The heated die presses onto the foil, transferring the desired design onto the label surface. This results in a crisp, durable, and shiny print that can highlight specific elements of a design, such as logos, brand names, or patterns.

The Visual Impact of Hot Stamping Labels

One of the most significant advantages of hot stamping is the visual impact it creates. A well-designed label using hot stamping can stand out on store shelves, making a product more appealing to consumers. The metallic sheen, paired with intricate detailing, conveys a sense of luxury and exclusivity that can elevate a brand’s image.

For instance, gold, silver, and holographic foils are commonly used in hot stamping to create stunning metallic effects. These elements can be used to highlight brand logos, add a touch of sparkle, or emphasize key product information. In addition to metallic shades, hot stamping also allows for colored foils, which can be customized to match brand colors for a cohesive look.

Why Brands Choose Hot Stamping Effects Labels

With lowering costs, there is greater prevalence of metallic effects in packaging. We see an increasing demand for embellishment in our target markets, and market pioneers additionally show a permanent interest in new embellishment technologies.

Hot stamping offers a multitude of benefits that make it a popular choice among brands looking to differentiate their products. Some of the main reasons include:

- Premium Appeal: The metallic finish created by hot stamping gives products a premium look that can attract higher-end consumers. This is especially useful for luxury items, such as perfumes, high-end chocolates, and premium beverages.

- Durability and Longevity: Unlike standard printing, hot stamping offers a more durable finish. The heat and pressure involved in the process ensure that the design remains intact, even in challenging conditions. This is crucial for products that might face varying temperatures or moisture levels during shipping and storage.

- Customization and Versatility: Hot stamping is highly customizable. Brands can choose from a wide range of foil colors, finishes, and textures to create unique designs that resonate with their target audience. This level of customization allows brands to align their label designs with seasonal themes or special product editions.

- Sustainable Foil Options: With growing concern for environmental sustainability, many foil manufacturers now offer eco-friendly foil options for hot stamping. These materials have a lower environmental impact, aligning with brands that prioritize sustainability in their packaging.

Trends in Hot Stamping Effects Labels

With lower costs associated with metallic enhancements, more markets are taking advantage of this packaging trend. Truthfully, any market can benefit from foil enhancements from the premium or luxury space down to the commodity items.Foil has become such a heavily used and affordable marketing medium that it’s a requirement of most brand owners today rather than the exception.

As consumer preferences evolve, so do the trends in label design. In recent years, hot stamping has been at the forefront of label innovation, with new techniques and styles emerging to meet the demands of modern branding. Here are some of the most popular trends:

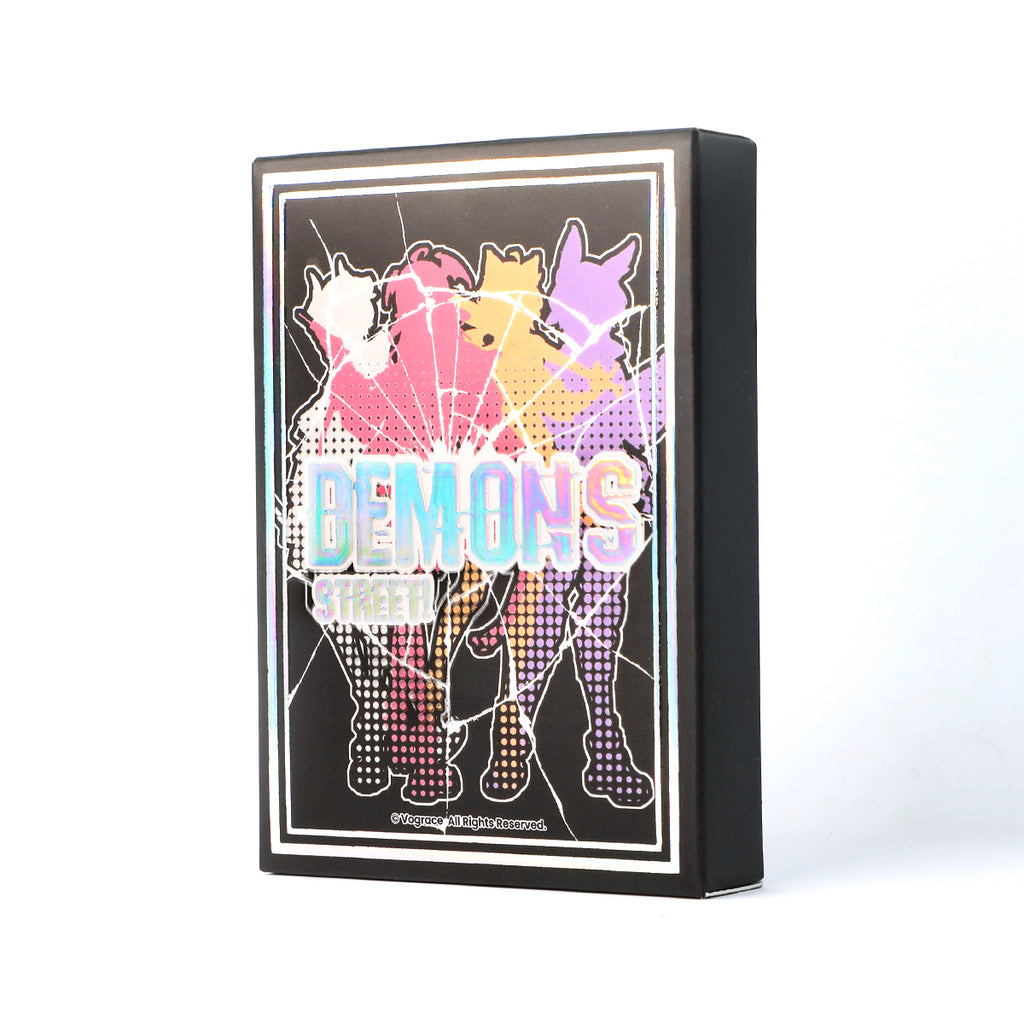

- Holographic Foils for a Dynamic Look: Holographic foils have gained popularity for their ability to create a multi-dimensional look that changes as the light hits the label. This eye-catching effect can enhance the visual appeal of products, making them stand out in competitive retail environments. Holographic hot stamping is particularly favored in the beauty and tech industries, where brands aim to convey a futuristic or vibrant aesthetic.

- Minimalist Designs with Metallic Accents: While the metallic finish of hot stamping inherently draws attention, many brands are opting for a minimalist approach where metallic elements are used as subtle accents. This approach allows brands to maintain a clean, modern look while still benefiting from the luxurious feel of metallic foils. For example, a simple silver-foil logo on a matte black label can create a striking yet understated appearance.

- Custom Texture Foils: Another trend in hot stamping involves the use of custom texture foils, which add both visual and tactile elements to a label. Textured foils can mimic surfaces like leather, wood grain, or even fabric, giving products a distinctive feel when consumers pick them up. This trend is especially relevant for brands that want their packaging to offer a sensory experience beyond visual appeal.

- Multi-Foil Layers: Advanced hot stamping techniques now allow for the layering of multiple foils on a single label, creating a rich, layered look. By combining different colors and finishes, brands can achieve a more dynamic and sophisticated design. This trend is ideal for limited edition products or brands looking to highlight their innovation and creativity through their packaging.

Challenges in Hot Stamping Effects Labels

Despite its advantages, hot stamping does come with a few challenges that brands should consider when opting for this technique:

- Cost: Hot stamping can be more expensive than standard printing methods due to the specialized materials and machinery required. The cost can vary depending on the complexity of the design and the type of foil used. For small businesses, the investment might be higher initially, but the enhanced brand image can often justify the expense in the long run.

- Limited Design Adjustments: Once a hot stamping die is created, it is challenging to make design adjustments without creating a new die. This can be a limitation for brands that frequently change their label designs or offer seasonal products.

- Production Speed: Hot stamping may take longer to produce compared to traditional digital printing, especially when intricate designs are involved. This might not be ideal for brands that require a fast turnaround time for their labels.

Best Practices for Implementing Hot Stamping Labels

To get the most out of hot stamping, brands should keep a few best practices in mind:

- Work with Experienced Printers: Given the precision required for hot stamping, it’s important to work with printers who have expertise in this area. They can guide you through selecting the right foils, designing for the stamping process, and ensuring that the final product meets your expectations.

- Consider the Substrate: Different materials react differently to heat and pressure, which can affect the outcome of hot stamping. Ensure that the substrate used for the label is compatible with hot stamping to achieve the best results. For example, certain plastic materials might be more suitable for foil transfer than others.

- Balance Design Complexity with Budget: While intricate designs can be stunning, they may require more expensive dies and longer production times. Brands should find a balance between the complexity of their design and their budget constraints to ensure they get the best value from the hot stamping process.

- Test Samples: Before committing to a large print run, it’s advisable to test samples of the hot-stamped label. This allows brands to see how the foil interacts with their design and make any necessary adjustments before full production.

The Future of Hot Stamping Effects Labels

The future of hot stamping effects labels is promising, with new technologies and innovations on the horizon. As brands continue to seek ways to differentiate themselves, the demand for high-quality, visually captivating labels will only grow. Some upcoming trends include digital hot stamping, which combines the precision of digital printing with the allure of metallic foils, and the development of biodegradable foils for eco-conscious brands.

Moreover, as consumer preferences lean more towards personalization, the ability to create custom, limited-edition packaging through hot stamping could become a key differentiator. This trend aligns well with the rise of direct-to-consumer brands, where packaging plays a vital role in the overall brand experience.

Conclusion: The Enduring Appeal of Hot Stamping

Digital printing produces metallic labels with high-quality color. Some UV digital presses enable converters to print multiple hits of white or clear to add label texture, as well. However, the majority of digital presses require post-finishing to produce labels with special effects. In today’s market, we see diverse brands using metallic labels for differentiation. A key factor with regard to digital presses is their ability to personalize or add variable data, a big reason for moving to digital or hybrid printing.

Hot stamping effects labels offer a unique blend of visual appeal, durability, and customization that makes them a valuable tool for brands looking to make a statement. Whether it’s adding a touch of luxury to a perfume bottle or giving a high-tech look to an electronic device, hot stamping continues to be a preferred choice for brands aiming to enhance their product’s shelf presence.

With the right approach, hot stamping can be a worthwhile investment that pays off in consumer interest and brand loyalty. As the market for high-quality, eye-catching labels continues to grow, hot stamping remains at the forefront of label design innovation—ensuring that products don't just compete but truly shine.